Accelerating Transformation — It All Starts with a New Production Line

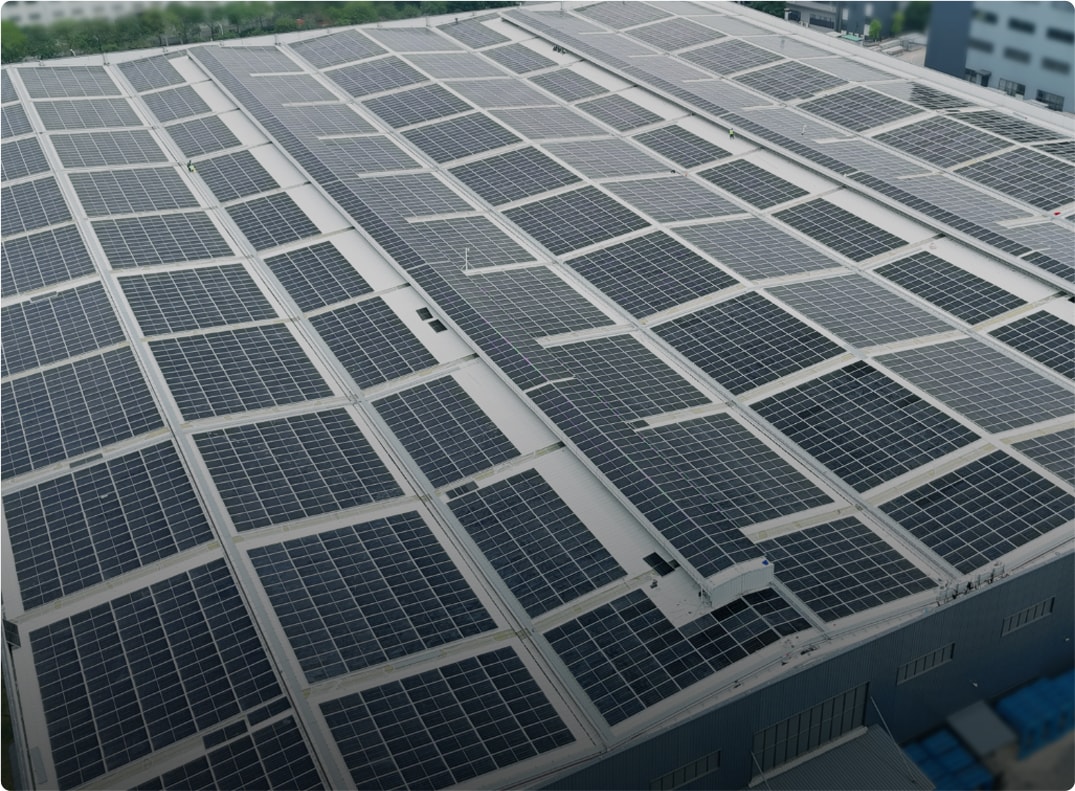

As demand for clean energy grows, solar mounting systems connecting PV modules to real installations face higher expectations. They must be strong, delivered quickly and maintain consistent quality. To meet these challenges, we've launched a new generation C-section steel production line, purpose-built to elevate our solar manufacturing capabilities.

From Output Efficiency to Smart Manufacturing

The new fully automated production line produces more than twice the output per shift than our previous lines. Because it requires far fewer operators, the overall production process has become more efficient and stable. With consistent performance throughout a 10-hour shift, the line is well suited for ground-mounted systems, rooftop PV projects and large-scale international orders.

A Smarter C-Channel Line — Not Just Faster

This production line integrates feeding, leveling, punching, roll forming, stacking and packaging with full-process coordination, greatly enhancing the structural stability and dimensional consistency of C-section steel. Multi-size adaptability allows flexible response to diverse project needs and site conditions.

Manufacturing for the Future of Solar

This upgrade represents more than a hardware change—it reflects our evolving mindset toward intelligent solar manufacturing. Through reduced energy use, higher product yield and synchronized automation, we're building a forward-looking production ecosystem where "faster" also means "better."

Efficient, Precise, Reliable — Built into Every Structure

We remain committed to advancing intelligent production of PV structures and solar mounting systems while developing manufacturing capabilities that are flexible, scalable and sustainable. Each new line not only increases capacity but also strengthens long-term competitiveness.

Want to learn more about our PV mounting products and solar manufacturing capabilities? Reach out to us today.

![[HOME]](/static/home/images/zimg62.svg)